- #Rotary vacuum filter vegetable oil how to

- #Rotary vacuum filter vegetable oil professional

- #Rotary vacuum filter vegetable oil series

The first one is a direct drive, which is connected to the rotating power source, in most cases an electric motor, through a crankshaft and coupling. There are several types of drives that power the vacuum pump rotor. Conversely, these vanes and rotor housing are sealed by a specifically formulated, low vapor pressure, oil which acts as a sealant, lubricant, and coolant of the vacuum pump. The Vanes are spring loaded which is how these create an air-tight seal between the rotor and the pump chamber housing.

As the rotor rotates, it pushes the gas molecules around the pump chamber and towards the exhaust where it is expelled to the atmosphere. The Gas Enters the Suction Chamber and is immediately compressed by the vane of the rotor.

#Rotary vacuum filter vegetable oil how to

How to get the best vacuum pump at the best price The quality difference between each vacuum pump and why some cost $100 and others $10,000ħ. Performance of a Rotary Vane vacuum Pumpĥ.Ědvantages and Disadvantages of Rotary Vane Vacuum PumpsĦ. The goal of this write up is to help you fully understand rotary vane vacuum pumps.īy the end of the article you will understand the following:Ĥ. Luckily, this article is here to help answer some of these questions. I would imagine that you immediately ask yourself what the deal here is. On one website, the vacuum pump is less than $100 on another website, you see a vacuum pump quoted at $10,000.

Perhaps you have noticed that rotary vane vacuum pumps come in all shapes and sizes. We will touch upon how they work, what they are used for, when to utilize a rotary vane vacuum pump, its advantages and disadvantages. In the article we are going to cover rotary vane vacuum pumps. When the thickness of the residual pre-coat is less than 10mm, it needs pre-coating again.Rotary Vane Vacuum Pumps, The Definitive Guide Meanwhile the solid powder or other foreign impurities in the material is counterchecked by the pre-coat then removed by movable peeler continuously. Under the function of vacuum, filter liquid goes through subsequently the pre-coat layer, filter cloth, imbibing tube, filter liquid collection pipe, and vapor liquid separator then enters into next processing section. Processing material is filtered into the bottom basin of the equipment.

#Rotary vacuum filter vegetable oil series

It is suitable for the process which needs filtration and doesn't need filter residue.

#Rotary vacuum filter vegetable oil professional

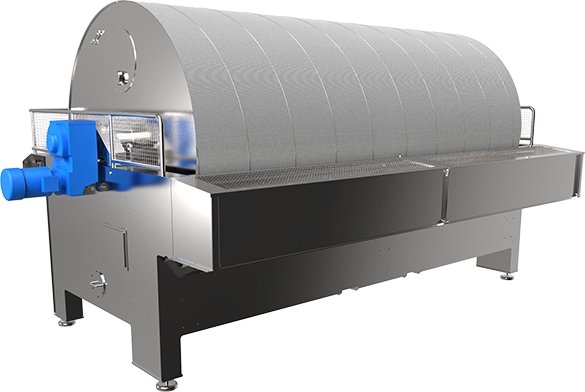

The professional manufacturing technique and advanced design idea make it be widely used in pharmacy industy, foodstuff industry and starch glucose making industry. MKPF external vacuum rotary drum filter is developed and manufactured by absorbing European advanced technology.

0 kommentar(er)

0 kommentar(er)